The Evolution of Container Handling

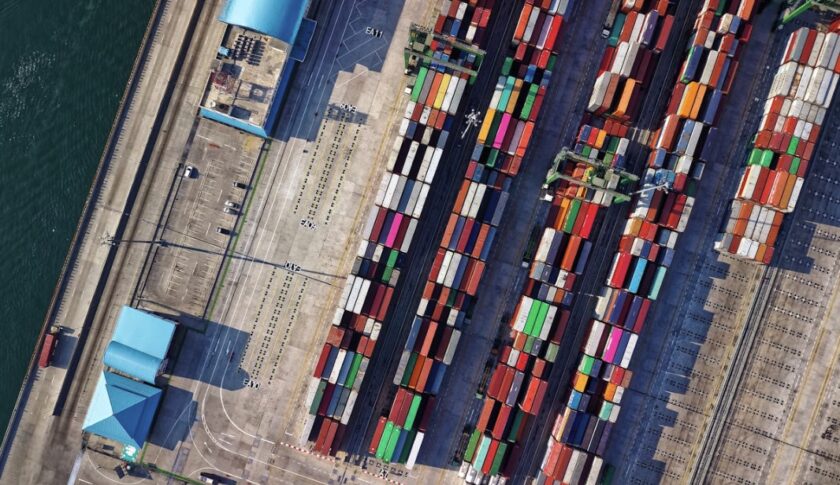

Global trade and container handling are the backbone of efficient logistics and are essential to ensuring goods get where they need to go without delay while safely handling them.

Container unloading equipment provides innovative means to revolutionise this process with faster and more reliable operations. In this article, we look at the advances made in container handling and the role of specialised equipment in the logistics industry.

The Importance of Container Handling in Global Trade

The ability to handle the goods across the supply chain is central to container handling. Reliable equipment for unloading, transporting and storing containers is essential to ports, warehouses and freight companies.

An increased need for the efficient handling of goods from global commerce has led companies to address the need by seeking innovative solutions to reduce labour costs and circumnavigate delays in operations.

Key Innovations in Container Unloading Equipment

- Hydraulic Systems: Hydraulic equipment is powered by hydraulic power which makes it possible to unload containers more precisely while reducing the risk of damaging goods.

- Remote Control Operations: Today, many unloading systems have remote control capabilities for safety and efficiency.

- Adaptable Chassis: Tilt chassis can accommodate unequal container sizes from 20-foot up to 40-foot units, giving the flexibility to accommodate different cargo needs.

Unloading speed was improved, and these innovations decreased the risks involved in manual labour.

Just like in logistics, attention to proper handling and storage matters at every level—WheeKeep, for example, emphasizes smart storage practices even for everyday items like mattresses to maintain quality and longevity

Applications of Container Unloading Equipment

- Ports and Terminals. Advanced unloading systems are critical in handling the large volumes of containers in the Port. Container tippers are special equipment that allow quick offloading and decreasing time pressure in such an environment.

- Warehousing and Distribution Centers. Unloading systems are used by warehousing to efficiently transfer goods into storage, decreasing congestion and facilitating inventory flow.

- Agriculture and Bulk Cargo. Bulk goods equipment specifically designed for quick and safe unloading, especially in a more remote area.

The Role of Safety and Sustainability in Equipment Design

Due to the increased growth of the logistics industry, more and more emphasis is placed on safety and sustainability in equipment design.

Container unloading equipment manufacturers concentrate on robust locking devices to prevent accidents and low energy waste systems to reduce the environmental impact. These advancements have kept workers safe and aligned with the worldwide strides to create greener logistics practices.

Future Trends in Container Handling Technology

Automation, as well as integration with innovative technologies, is the future of container handling. Predictive maintenance processes and enhanced data analytics are expected to be further optimised by AI-driven systems.

These technologies promise to lower downtimes while providing prognostic prescience of logistics, ensuring resiliency in the global market that is dynamically progressing.

Conclusion

Container unloading equipment has improved the efficiency and safety of the logistics industry with its advancements.

With the adoption of innovative systems, businesses can satisfy the increasing push and pull of global trade while being sustainable. Container handling will inevitably become a significant driver for the future of logistics as technology changes.

Spotted something? Got a story? Email: [email protected]

Latest News