How 3D Printing Works: A Journey from Digital to Physical

magine holding an object with intricate and complex details in your hand after it was merely an idea in your head a few hours ago. It came to life, layer by layer, in front of your eyes. This is the wonder of 3D printing. It is changing the manufacturing landscape as we know it and causing us to re-imagine innovation in nearly every industry. But how does all this work?

The Basics of 3D Printing

3D printing is a manufacturing technique used to produce three-dimensional (3D) objects by adding material on top of the object in the making in layers, right from the digital file. The work is exactly opposite to conventional methods where the material is either cut from the base, or just a mold being filled.

The process starts once a 3D digital model is made, mostly using CAD (Computer-Aided Design) software. The printing software divides the digital model into multiple horizontal layers and acts as a guide to create the printing path.

The Printing Process

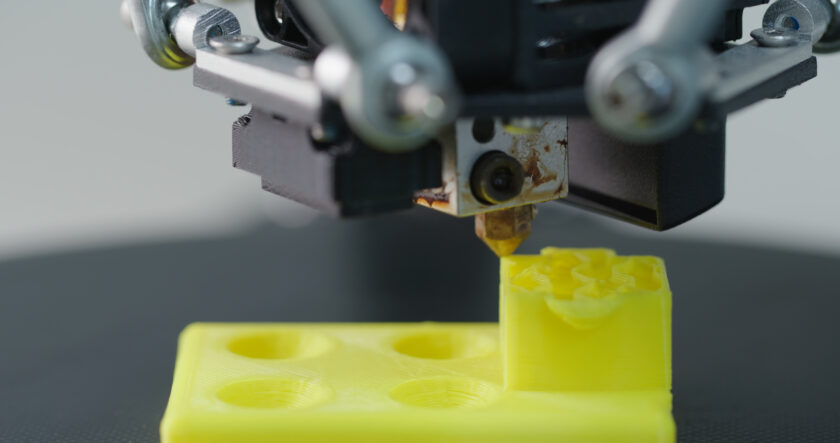

After the digital file is developed and fed into the computer, the 3D printer takes control. It builds the object layer by layer, following instructions in the sliced design. The material used often is a form of resin, plastic, metal, or food ingredients. The nozzle moves from side to side depositing material. Another type of 3D printer uses lasers to fuse material. Whichever method is used, both are adding materials, or cutting down to shape, the object layer by layer.

Types of 3D Printing

There are several different methods of 3D printing, and the type of printer you have will dictate its capabilities:

- Fused Deposition Modeling (FDM): FDM is a relatively common method that involves extruding melted plastic through a nozzle. It is used for prototyping, small-scale production, and in most popular 3D printers.

- Stereolithography (SLA): This printer uses a laser to harden liquid resin into hardened plastic. SLA printing is known for producing prints with very high resolution and smooth surfaces.

- Selective Laser Sintering (SLS): In SLS printers a laser is used to heat and sinter together material powder (examples include nylon or metals) layer by layer.

Each method has its pros and cons. The specifics of its use case and what material, finish, and use the end object has will determine the final result.

The Versatility of 3D Printing

3D printing is a versatile technology. Applications range anywhere from rapid prototyping to fabricating custom medical and aerospace hardware. Further, the benefits of on-demand customization and rapid production have brought 3D printing to healthcare, fashion, and even the culinary scene.

In the automotive industry, spare parts can be printed on the spot with the exact materials, color, and specifications needed, reducing the size of necessary inventory. In medicine, it allows physicians to print out patient-specific implants and prosthetics for better treatment. But this isn’t the limit.

Exploring 3D Printing Services

Whether you are eager to explore the 3D printing craze or are already convinced about its exceptional qualities and benefits, the great news is you don’t have to have your 3D printer to start experimenting. 3D-printing services such as FAMA 3D offer a terrific opportunity to help you with the realization of your projects. Whether you want to print out a fun project you just finished working on or bring your prototype to life, they can bring their experience and technology together to make your vision come true.

Most will also offer guidance for material selection and printing techniques to provide you with the best results depending on your specific design, and assistance with the printability and functionality of the digital model you are about to print.

The Future of 3D Printing

Besides manufacturing, 3D printing has innumerable applications today. As technology advances, so do the options for materials, speed, and accuracy. It’s only a matter of time before we can print virtually anything from the comfort of our own homes, much like we can with traditional printers today.

Whether you’re fabricating intricate scale models or prototyping a seemingly one-off part, 3D printing is the path of least resistance toward turning an idea into a prototype. Plus, with a service like FAMA 3D, the entire process is more accessible than ever.